There are different mediums that welders use depending on their specific project needs. Two of the welding types are MIG and TIG. While both techniques use an electric arc to make the weld, the process for each is vastly different.

Determining a Method

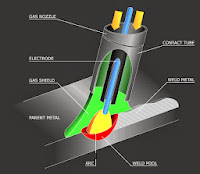

MIG (metal inert gas) welding is the easier of the

two methods and uses a continuous wire feed as an electrode and an inert or

semi-inert gas mixture to protect the weld from contamination. Wire is

continuously fed through, then burns, melts and fuses the two pieces of metal

together. Since the electrode is

continuous, welding speeds are greater. As a faster and cheaper process of welding, it is

used for anything from hobbies to shipbuilding.

Using this method, you can weld together mild steel, stainless steel,

aluminum, etc. MIG welding can be used

to weld materials from thin sheet metal to heavy structural plates.

TIG (tungsten inert gas) welding is a manual

welding process that uses a nonconsumable electrode made of tungsten, an inert

or semi-inert gas mixture, and a separate filler material. TIG welding is more specifically used

for thinner gauge materials, as it allows you to not burn through the metal. It requires

significant operator skill and can only be accomplished at relatively low

speeds. As a

more mild welding technique, TIG welding is commonly used when the weld

integrity is critical as it provides a more precise weld. Offering better heat

control, this style of welding also produces stronger welds. Since the weld

yields an aesthetic surface finish, it also does not require any grinding. TIG

welding is a cleaner style of welding that produces less fumes and sparks than

MIG welding. Typical applications range from stainless steel fabrications to

delicate materials such as jewelry.

MIG Welding

|

TIG Welding

|

▪

Easiest of the welding methods

|

▪

Produces the best looking weld

|

▪

Not preferred for thin gauge steel (burn through)

|

▪

Can fuse metal together without filler material

|

▪

Cheaper than TIG Welding

|

▪

More expensive than MIG welding

|

Sheet Metal Unlimited is capable of using either procedure to provide the product you need when you need it. To discuss your plans specifically and get a quote for your next job, contact us today!

Both MIG and TIG welds are types of arc welding, which utilizes the concentrated heat of an electric arc to join together metals by fusion of the parent metal by a consumable electrode.

ReplyDeleteGreat post : " What is the difference between MIG and TIG welding?". I found it very useful and informative.

ReplyDeleteAFAB Enterprises offers precision CNC machining, custom fasteners, repairs, and more. Call one of the most trusted machine shops Florida has to offer!

Also visit refractometer.com for Refractometers of all kinds. Also more details click custom fasteners

Thanks -

Awesome post: "What is the difference between MIG and TIG welding?". Very informative one. Regards,

ReplyDeleteAFAB Enterprises offers precision CNC machining, custom fasteners, repairs, and more. Call one of the most trusted machine shops Florida has to offer!

Also visit refractometer.com for Refractometers of all kinds. Also more details click custom fasteners

Thanks -

I understand the difference in technique. What is the difference in effectiveness? Does one last longer than the other.

ReplyDeleteElisa Jed | http://www.academysheetmetal.com.au

My parents are looking for someone who is willing to do some metal fabrication for their house. They want to make their dining room look like an old diner and they want to put some metal paneling on the wall to make it look like an old diner as well. No one provides exactly what they are looking for, so right now they are looking for someone to custom make the panels. How can I find metal fabricators who live near them? http://www.metalfab.com

ReplyDeleteYa know, I really did learn something from reading this article. I had a faint idea of the difference between MIG and TIG welding, but now I know a lot more. With welding comes metal fabrication, and with fabrication come expenses. Doing your own metal fabrication can be cheap, but you never know the outcome of the product. If I was going to get some sheet metal work done, I would want to put it in the hands of a professional. http://www.academysheetmetal.com.au/steel-fabrication/

ReplyDeleteThanks for sharing the differences between MIG and TIG! I hope that the best steel fabricators in the Philippines know the difference of this.

ReplyDeleteThank you for sharing this informative topic about the difference between MIG and TIG. I hope these ideas would be understand more by Sheet Metal Worker. Anyways, speaking of Sheet Metal Worker. I heard that Jobstar.net.au (It's a jobsite) whose currently looking for Sheet Metal Worker Jobs in Brookvale NSW. If you are interested, feel free to apply and visit to their website here.

ReplyDeleteGaming pc’s aren’t as difficult as you may perhaps think, and creating your very own gaming pc is not as tricky as a whole lot of folks would make you consider. Because you by now have a distinct software in head when constructing your individual gaming machine, there are actually only three main elements you have to have to worry about, and every little thing else is truly secondary: the processor, video clip card, and RAM. more tips here

ReplyDelete